3D printing is a rapidly growing industry, and it can be hard to keep up with all the new developments. That's why we've written this guide! We'll dig into some of the ins and outs of how 3D printers work, examine their advantages over traditional manufacturing methods, compare different types of 3D printers, and discuss where they're used.

How does a 3D printer work?

To understand how 3D printing works, you need to know what a 3D printer is and how it works. In this section, we'll explain the basics of additive manufacturing (the process of creating objects by adding material layer-by-layer). We'll also cover some example 3D printers that illustrate different kinds of technologies and applications.

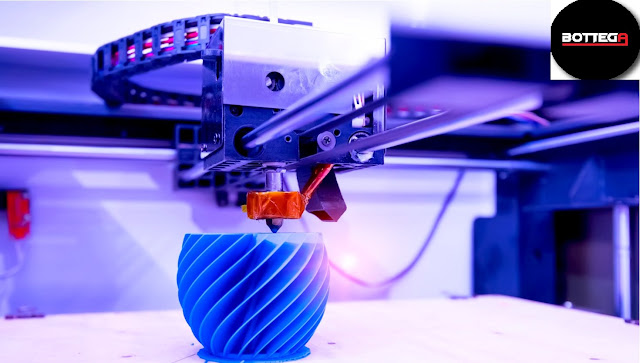

A 3D printer is an industrial machine used to create three-dimensional solid objects from digital models by depositing materials in successive layers until those objects are formed. The most common types of additive manufacturing technologies use plastic or metal as building materials; however there are also other options such as paper pulp or even food!

Fused Deposition Modeling (FDM) machines work by heating up plastic filament until it becomes liquid; this molten material then cools into solid form once extruded onto a platform inside the printer's build chamber. As more layers are added on top of each other, they create objects with varying degrees of detail depending on how finely granulated each layer is printed out--from rough surface textures all way down through smooth lines & curves!

Advantages of 3D printing

You can use this technology to make one-off items, such as prototypes or specialised tools and fixtures, which are difficult or expensive to produce using traditional methods. This ability also makes 3D printing ideal for manufacturing parts that require complex geometries or intricate details.

The second major benefit of additive manufacturing is reduced waste during production. Even though the cost per unit produced may be higher than other processes like subtractive milling or casting, once you've made your design there will be no waste materials left over - saving both time and money on disposal costs!

Where does 3D printing take place?

In a factory, 3D printing takes place in a clean room. This is because the machine is large and creates some amount of dust as it runs. The printer itself is also very loud, so workers need to wear ear protection when they're working with it.

The 3D printer can be used to make many different things: from medical devices like prosthetics or implants to toys or clothes (like this dress).

3D printing is a very useful technology that we can use to make many different things. It’s also fun and easy to use, so it’s no surprise that more and more people are getting interested in it.

Conclusion

3D printing is an exciting technology that has many benefits. It can be used to create objects that would otherwise be impossible to make with traditional manufacturing methods, such as injection molding or casting. 3D printers allow designers to iterate more quickly and efficiently than ever before, allowing them to produce prototypes of their designs at a lower cost than previous methods required.

Source By - https://bit.ly/3IEKWUM