In the ever-evolving world of precision engineering and CNC machining, the quest for economical yet high-quality solutions has never been more pressing. Whether you're a seasoned professional or just stepping into the world of precision manufacturing, finding the right CNC machining accessories is a paramount consideration. In this article, we'll introduce you to a comprehensive total solution that blends affordability with top-notch quality, all the way from China. Silvercnc, a leading name in the industry, brings forth a remarkable range of CNC machining accessories that cater to the diverse needs of businesses worldwide. From toolholders and workholding solutions to cutting tools and everything in between, Silvercnc has your needs covered. So, let's embark on a journey to explore how Silvercnc is redefining the standards of CNC machining accessories, offering both cost-effectiveness and uncompromising quality to fuel your manufacturing success.

Silvercnc is your one-stop destination for affordable CNC machining accessories that cover a wide spectrum of your precision engineering needs. Among their extensive offerings, you'll find a diverse range of essential tools and components, all designed to enhance the efficiency and precision of your machining operations.

First on the list are their rotary tables, which are available in various configurations to suit different machining requirements. Whether you're in need of a 4-axis rotary table, a 5-axis tilting rotary table, a horizontal table, or a tailstock, Silvercnc has you covered. These rotary tables are pivotal in achieving multi-axis machining and can significantly expand the capabilities of your CNC machine.

Silvercnc's commitment to precision extends to their probing systems. They offer optical touch probes, radio wave touch probes, and wired touch probes, all of which play a crucial role in enhancing measurement accuracy during machining. These systems are essential for tasks like workpiece inspection, ensuring that your machining processes meet the highest quality standards.

In addition to probing systems, Silvercnc provides a range of tool setting solutions. From laser tool setters to touch trigger tool setters and optoelectronic tool setters, you'll find the right tool for maintaining precise tool measurements. These systems contribute to the consistent and high-quality machining results that are essential for any precision engineering operation.

Lastly, Silvercnc offers a selection of zero point systems, which are indispensable for efficient workholding and workpiece changeovers. Whether you opt for their zero point clamping system, mechanical zero point, or self-centering vise, these components are designed to reduce setup time, enhance repeatability, and optimize overall production efficiency.

In the realm of affordable CNC machining accessories, Silvercnc stands as a reliable and comprehensive source. Their range of products covers all the crucial aspects of CNC machining, ensuring that your operations benefit from enhanced precision, cost-effectiveness, and efficiency. Whether you're a seasoned professional or just starting in precision engineering, Silvercnc provides the tools you need to achieve outstanding results.

CNC Machining Accessories:

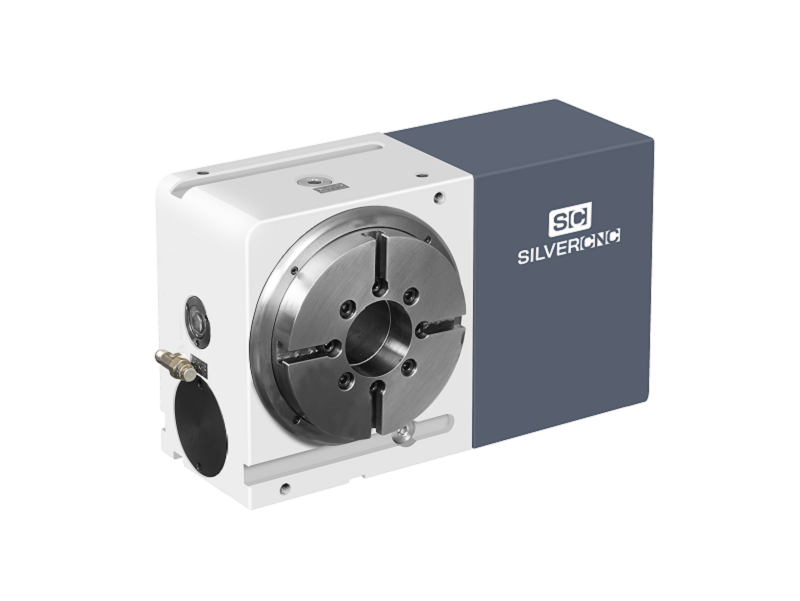

4 Axis rotary table

CNC machining accessories are integral components in the world of precision engineering, enabling businesses to achieve advanced machining capabilities. Among these accessories, the 4-axis rotary table stands out as a versatile and pivotal tool. This ingenious device extends the capabilities of CNC machines, allowing for multi-axis machining, intricate part production, and enhanced precision. With the ability to rotate workpieces along four axes, it provides a dynamic platform for complex machining operations.

The 4-axis rotary table is indispensable for tasks that demand intricate designs and precise contours, making it a valuable asset for industries ranging from aerospace and automotive to medical device manufacturing. In the realm of CNC machining accessories, the 4-axis rotary table plays a crucial role in transforming designs into reality with unparalleled accuracy and efficiency.

Touch Probe

CNC machining accessories play a fundamental role in enhancing the precision and efficiency of machining processes, and among these accessories is the Touch Probe, proudly manufactured by Silvercnc. This precision instrument is a key component in CNC machining, enabling highly accurate measurement and inspection of workpieces during the manufacturing process. Silvercnc's Touch Probe is a testament to their commitment to delivering quality accessories for precision engineering. It allows for precise and reliable data collection, contributing to the overall quality control and accuracy of CNC machining operations. Whether used for part inspection or tool measurement, Silvercnc's Touch Probe is designed to meet the rigorous demands of modern manufacturing, making it an indispensable asset for businesses looking to achieve excellence in CNC machining.

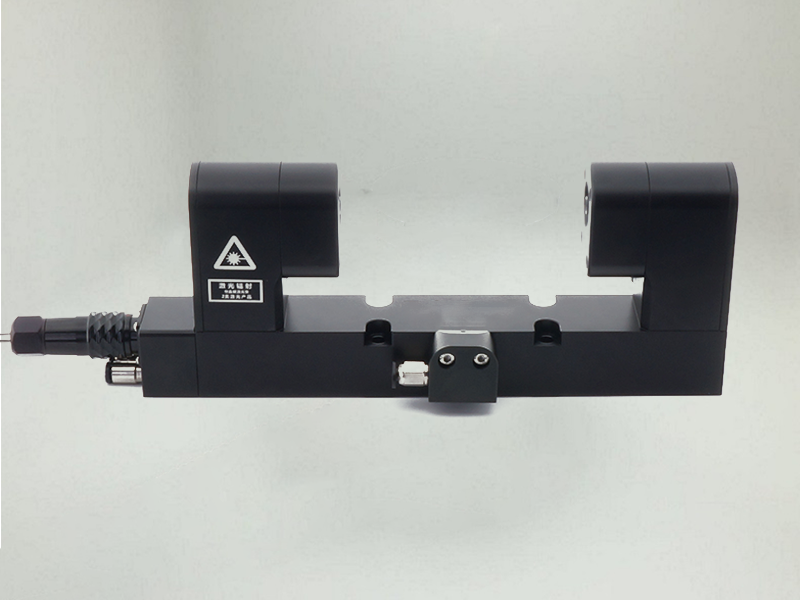

Tool Setter

In the world of CNC machining accessories, precision is paramount, and the Tool Setter, proudly manufactured by Silvercnc, stands as a testament to this commitment. This essential tool plays a pivotal role in maintaining the accuracy and efficiency of CNC machining operations. Silvercnc's Tool Setter is a high-quality component designed to ensure precise tool measurements, thereby enhancing the overall precision of the machining process. It offers a dependable solution for setting and calibrating tools, contributing to reduced setup time and minimized machining errors. Whether you're utilizing a laser tool setter, a touch trigger tool setter, or an optoelectronic tool setter, Silvercnc's range of Tool Setters is engineered to meet the exacting demands of modern manufacturing, providing businesses with the tools they need to achieve superior quality and precision in CNC machining.

Mechanical zero point clamping

In the realm of CNC machining accessories, precision engineering and workholding solutions are essential for maintaining accuracy and efficiency in machining operations. Silvercnc offers a highly reliable and efficient solution in the form of their Mechanical Zero Point Clamping system. Manufactured with precision and quality in mind, this system is a fundamental component in securing workpieces during machining.

The Mechanical Zero Point Clamping system, produced by Silvercnc, simplifies the process of changing workpieces and fixtures, contributing to reduced setup times and increased productivity. Its robust and durable design ensures long-lasting performance, making it an indispensable asset for businesses seeking to optimize their CNC machining processes. With Silvercnc's Mechanical Zero Point Clamping, precision and efficiency go hand in hand, ensuring that every machining task is executed with the utmost accuracy and reliability.

In conclusion, the quest for economical yet high-quality CNC machining accessories has found a worthy solution in Silvercnc. We've explored the extensive range of offerings from this reputable source in China, highlighting the perfect blend of affordability and precision. Silvercnc's commitment to delivering a comprehensive total solution, whether it's toolholders, workholding solutions, or cutting tools, demonstrates a dedication to supporting businesses on their journey to precision manufacturing success. By choosing Silvercnc, you're not only securing cost-effective solutions, but you're also investing in the quality and innovation that can elevate your CNC machining operations. The world of CNC machining accessories has a new benchmark, and it's set by Silvercnc's commitment to providing total solutions that meet your needs and exceed your expectations.