Specialty gases play a pivotal role in various high-precision applications, from scientific research to the production of electronic components. Unlike their industrial counterparts, these gases boast higher purity levels and more stringent quality control measures, which are crucial for the specific processes they facilitate. Exploring the distinctions between specialty and industrial gases presents an opportunity to understand their unique characteristics, applications, and handling requirements. Keep reading to delve into the world of specialty gases and grasp their integral role in numerous industries.

Understanding the Basics of Specialty Gases

Specialty gases refer to a group of gases that are designed for specific industrial and analytical applications requiring the highest levels of purity and consistency. The term encompasses a wide array of gases, including noble gases like argon and helium, as well as reactive gases such as hydrogen chloride and sulfur hexafluoride. Given their specialized nature, these gases necessitate careful production and quality assurance to meet the exacting standards demanded by end users.

The production of specialty gases involves meticulous purification processes to eliminate contaminants that may interfere with their intended use. The focus on precision extends to the calibration of gas mixtures, ensuring that each component is present in the exact concentration required for an application. Such precision is fundamental, as even minute discrepancies can lead to significant variances in outcomes, particularly in sensitive environments like laboratories or semiconductor fabrication plants.

Sourcing specialty gases often means turning to a reputed specialty gas supplier since 1937. Suppliers like these are equipped with the knowledge and infrastructure to handle the delicate nature of these gases, providing products that adhere to stringent certifications and standards. This level of specialty service is a testament to the critical nature of specialty gases in high-stakes applications.

Unique Applications for Specialty Gases in Various Industries

Specialty gases find applications across a plethora of industries, each with its particular requirements. In medicine, for example, ultra-high purity medical gases are used for anesthesia and patient monitoring, demanding absolute reliability for patient safety. Similarly, in the food and beverage sector, modified atmosphere packaging employs specialty gases to prolong shelf life and maintain product freshness without the need for preservatives.

Electronics and semiconductor manufacturing remain some of the largest consumers of specialty gases. These industries utilize gases such as silane, nitrogen trifluoride, and others in the production of microchips and circuit boards. The purity levels are critical as the miniaturization of electronic components continues; any contaminants can lead to defects that render these components useless.

How Specialty Gases Differ From Industrial Gases in Production and Handling

The production of specialty gases is markedly different from that of industrial gases. Industrial gases might tolerate some variability in purity, but specialty gases must conform to precise specifications. The production facilities for specialty gases are often separate from those of industrial gases, equipped with advanced purification systems and analytic instruments to perform the required quality control tasks.

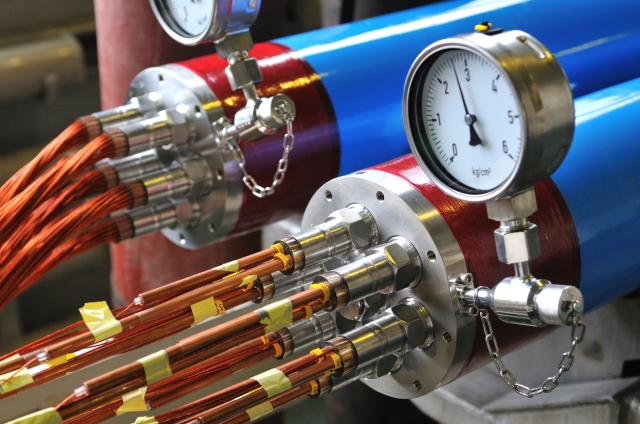

Handling specialty gases necessitates special considerations to maintain their purity and integrity. This might include the use of specialized gas-handling equipment such as high-purity regulators, valves, and fittings that are unlikely to contribute to contamination. Furthermore, specialists trained in managing the delicate nature of these gases are typically responsible for their handling to mitigate the risk of accidental contamination or improper usage.

Specialty gases are also subject to strict regulations when it comes to labeling and documentation. Each cylinder of gas is accompanied by extensive paperwork detailing its contents, origin, and suitability for various applications. In contrast, industrial gases are often delivered with more general information, reflecting the broader range of applications and less stringent requirements in their use.

The Role of Packaging and Transportation in Maintaining Specialty Gas Quality

Packaging and transportation play a crucial role in preserving the quality and purity of specialty gases from the point of production to their eventual use. Cylinders and containers designed for specialty gases are typically made from materials that will not react with the gas. These containers often undergo treatments such as passivation to further reduce the risk of contamination from the container walls.

In addition to high-integrity containers, the packaging often involves tamper-evident seals and sophisticated valve systems. The aim is to minimise exposure to the atmosphere, which could introduce moisture or other contaminants. The effort in packaging underscores the lengths vendors will go to ensure the integrity of the gas until it reaches the end user.

Overall, the noteworthy difference of specialty gases lies in their impeccable purity, regulated production, and the intricate applications they serve across various industries. Through the vigilant practices of production, handling, packaging, and transportation, the distinct nature of specialty gases is preserved, ensuring their critical role in driving the precision and innovation of many technological and scientific fields.